Just the right tension and effect

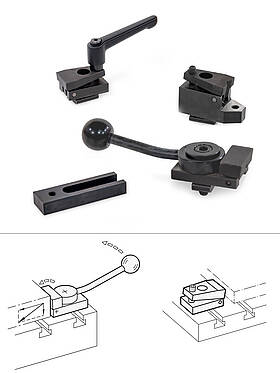

The new pull-down clamps with GN 9190.1 clamping thread can be fastened to a machine table or fixture by T-slots for easy machining of workpieces. The clamping force of the rotary-mounted clamping jaws acts both laterally and from above to pull down on the workpiece and clamp it against fixed stops and the supporting surface. Thanks to the low overall height of the pull-down clamps, the workpiece can be machined over its entire surface. Fluted or prismatic clamping jaws, as well as pull-down clamps with or without integrated support, are available depending on the application situation.

The pull-down clamps are also available with either a ball point screw or adjustable hand lever which includes an integrated ball point screw. The latter enables the clamping element to be actuated without tools. When the clamping screw is loosened, the jaws are retracted to their initial position through spring force and the workpiece is released.

For extremely quick and frequent clamping, Hanser also offers the GN 9190 pull-down clamp with a spiral tension lever. This generates its clamping force with a self-locking spiral that ensures constant forces at all times.

Hanser’s pull-down clamps are made of high-grade case-hardened steel, making them extremely durable and premium in quality. Hanser offers GN 9190.3 support strips in its range as matching accessories. They can be used to fasten pull-down clamps to machine tables in any position, even perpendicular to the T-slot.

Précédent